Transforming MDU and Residential Installations: Precision Group’s Tailored Solutions for ALLO Fiber

For the last 18 months, Precision Group has collaborated closely with ALLO Communication’s Business Team to develop a specialized backplate tailored for their high-density housing projects. Allo sought a solution to accommodate two Clearfield cassettes at the demarcation point of MDUs while also incorporating efficient cable management.

About ALLO Communications

ALLO is a telecommunications company offering fiber telephone, long-distance, broadband, internet, and television to residents and businesses. Allo currently provides communications services to 40 cities across Nebraska, Colorado, and Arizona totaling over 1.1 million in population.

The Challenge

ALLO was using a NEMA 3 18”x18”x6” metal enclosure and needed a better way to mount cassettes as well as have cable management capabilities. They also needed an all-weather solution that eliminated the need for tie wraps.

Erik Meyer, Field Service Manager and Matt Murray-Hansen, Field Operations Supervisor at ALLO, approached Joe Ascheman, Regional Account Manager at Precision Group, presenting the challenge of devising an all-weather solution that could integrate seamlessly with Clearfield’s cassettes while offering robust cable management features.

“We initially were having issues with our battery backup power supplies and started talking with the Precision Group team about MDU product solutions,” said Dan Erwin, Senior Manager Field Operations at ALLO Communications. “We wanted to know, how can we work better and more efficiently?”

“We were also specifically looking for a built-in solution to hide fiber behind a plate for cleaner MDU installations. With the hot and cold weather fluctuations we incur in Nebraska, we needed a sturdy solution protected inside a cabinet.”

“A common problem we were facing involved our use of tie wraps and plastic. The tie wraps would break in the cold which would lead to callouts on the weekends, increasing truck rolls. Once the tie-wraps would break the cassettes would slide in the box and break the fibers. Some of these cassettes were 8-port, 16-port, 32-port so we’d have multiple MDU’s down at one time, which is not suitable.”

The Solution

Precision Group rose to the challenge, delivering a customized solution for ALLO.

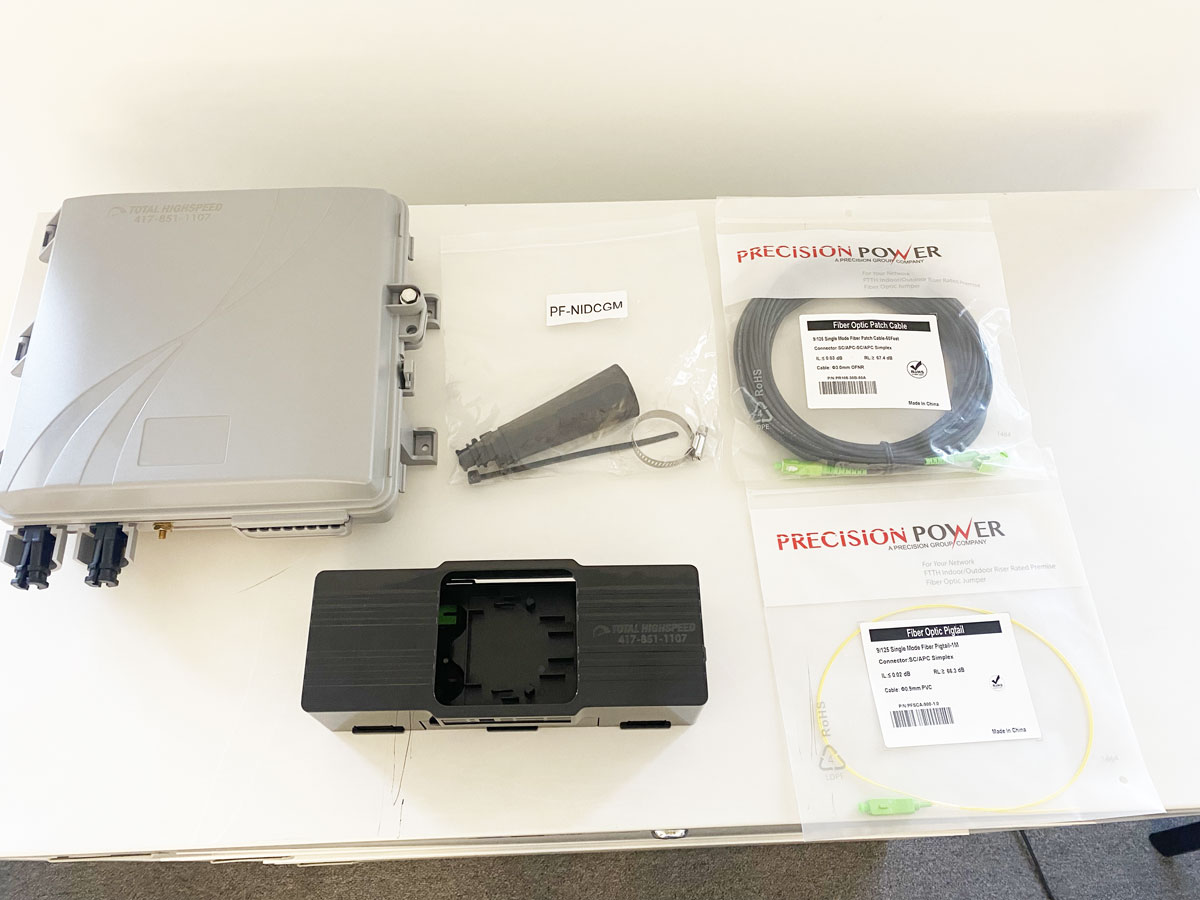

Deployed across Colorado, Arizona, and Nebraska, the final product features a fold-down plate facilitating efficient cable management, complete with placeholders for two Clearfield cassettes.

“We worked with Precision Group through several design iterations to manufacture a custom hardened plate insert for our MDU boxes,” said Erwin. “It was fun to be involved in the design process and challenge each other to think of different ways to solve the problem.

After the prototypes came out we started sharing pictures within our team here in Nebraska and Precision Group did some 3D demos online for team members across four states. The plates are now in the field and technicians installing these are reporting back that installs are simpler and faster.”

Taking Customer Input Seriously, Precision Group Redesigns M-Flex NID

“This was a jumping off point for Precision Group to build a deeper relationship with various team members at ALLO Fiber,” said Ascheman. “Our engineering team at Precision Group was already in process of redesigning our popular M-Flex NID and the opportunity to collaborate with ALLO’s residential team was invaluable.”

Ascheman and Bryan Hughes, VP-Sales at Precision Group encouraged the residential team at ALLO Fiber to look further at the M-Flex’ functionality and features and provide input on what they would like to see for streamlined installation and better customer experience.

The Challenge

This collaboration highlighted ALLO Fiber’s concern about drilling numerous holes directly into customers’ homes for aerial applications.

“Joe Ascheman and I met and kept flipping the M-Flex over and over,” said Erwin. “I showed him some pictures of the sides of homes in Arizona where we were having issues with stucco. We were performing aerial drops into the side of the house, coming down with our drip loop, and then going back up into the box.

The challenge is, if we ever needed to move the box, we would have to patch the customer’s stucco, which costs about $150 per hole to restore its original texture and color. We were looking for a solution that would not require us to put so many holes in the side of a customer’s house.”

The Solution

“We worked with the Precision Group team to brainstorm ways to make the install cleaner and eliminate excess holes,” said Erwin.

As a result, Flat-drop clips will be introduced on the side of the M-Flex NID to secure aerial drops, minimizing the need for anchor holes in residential properties.

“Dan and his team at ALLO proposed the idea of flat-drop channel,” Hughes noted. “And, feedback from other customers in the field has been overwhelmingly positive, applauding the ingenuity of the solution.”

The reinvented M-Flex (PF-MFLEX-NIDC01CS00-030) will be in production in summer of 2024.

Key modifications to the M-Flex will include:

Deeper Base – ½” Increase

- To provide room for I/O fiber spool (design requirement)

- To provide more clearance for the lid of the NID to open when applied to homes with siding (customer provided feedback)

Reduced Height of Splice Tray on Base

- Also to provide room for the I/O fiber spool (design requirement)

- Clear cover Splice Tray

Addition of a Push-Through Grommet

- Allows installer to enter the customer premise directly from the back of the NID (customer provided feedback)

Flat-Drop Channel

- Secures aerial drops with flat-drop clips (customer provided feedback)

Made by installers, for installers.

Better Connection. Better Experience. Problem Solved.

FIND A LOCAL REP

Sometimes you need someone who is close to you, to demonstrate products and walk through solutions on site. Precision Group has a team of local reps throughout the U.S. to help you solve problems. Contact Bryan Hughes to get connected to your local rep.