Moving the ONT Indoors: Simplifying Fiber Optic ONT Installs

For years, technicians have been mounting fiber optic ONTs (Optical Network Terminals) in outdoor NIDs or clamshell boxes. But as more service providers look to cut costs and simplify installs, those units are now being brought inside the home.

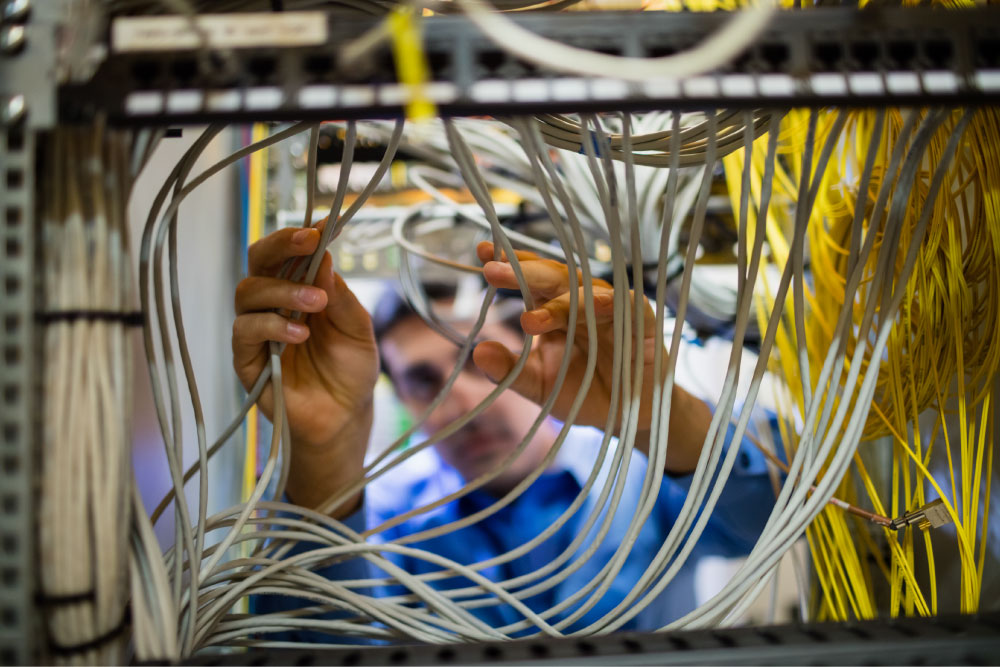

The catch? That transition can get messy — fast. Holes to patch, paint to match, and fiber spaghetti everywhere.

That’s where Precision Group’s Cable Management Transition Plate comes in. It’s a simple, smart fix that saves time, labor, and frustration during indoor ONT transitions.

“It Just Makes Sense for the Tech”

“You don’t have to take the NID off the side of the house,” says Sean Whalen, Director of Sales – East U.S. at Precision Group. “There’s no screw holes to patch, no faded paint issues. It’s quick, it’s cheaper, and it just makes sense for the technician.”

That’s exactly how Sean pitches it — because that’s exactly how it works.

Rather than replacing the existing ONT NID, incurring unneeded cost and potential damage to fiber or home, repurpose the ONT NID with the Precision Group Transition Plate. Simply decommission the existing ONT and seat the Transition Plate into the existing NID hinge clips, creating a clean transition point between the outdoor connection and the new indoor ONT.

Everything stays neat. Everything stays sealed. And the cut-over is quicker, cheaper, and cleaner.

Goodbye, Fiber Spaghetti

Ask any technician what happens when they don’t have proper cable management, and you’ll hear the same thing: fiber everywhere.

When an ONT gets moved indoors without a solution like this, slack fiber often ends up zip-tied, coiled, or shoved into the old NID box — creating a mess that’s just waiting to get pinched or broken later.

Sean explains it simply:

“Before, they’d have to zip tie the fiber to itself and shut the box. There’s no management whatsoever if they’re not using this.”

The Transition Plate changes that. It gives techs a place to safely store up to 100 feet of 3 mm fiber slack in cable management clips, or up to 150ft with a Jumper on a spool design that keeps everything tidy and protected. It’s the difference between a clean, professional install — and one that looks like spaghetti behind the siding.

Better Seals, Fewer Bugs, Less Rework

Beyond just cable management, Precision Group focused on the details that make a difference in the field. One of Sean’s favorite points to mention? The grommet.

The plate comes with a double-round split grommet that seals tighter around the fiber than most existing units, keeping out insects and moisture.

It’s one of those small touches that only someone who’s spent time on job sites would think to fix — and it’s exactly what Precision Group is known for.

Add-On Options That Work Smarter Together

Another smart move: the Transition Plate works seamlessly with the Locate Lug accessory.

When installing the plate, techs can also drop in the ground lug insert to tie a tracer wire from the outside — no need to open the NID later.

Sean explains, “If they’ve brought a tracer wire up to the NID, they can tie it to our insert lug during this transition. In the future, the locaters do not have to enter the NID, and potentially damage fiber, to complete a locate.”

That means fewer truck rolls and fewer headaches for everyone involved.

Built for Flexibility — Giving Techs Options, Not Limitations

One of the biggest benefits of the Transition Plate is how adaptable it is.

It works with Precision Group’s PF-ONT NID family, but it’s also compatible with most outdoor clamshell-style NIDs already in use.

“If you’re going from outdoor to indoor ONTs, you don’t have to remove what’s already there. You can just use this as your transition point,” Sean says. “You’ve got options — not limitations.”

That flexibility means ISPs can retrofit older installs, roll out new ones faster, and keep their techs working efficiently — no more wasted time removing old hardware or patching walls.

Saving Time and Money Where It Matters

Between labor and material costs, the savings add up fast.

Sean estimates the Transition Plate offers a 25–30% savings in material costs over replacing a full NID — plus at least an hour of technician time saved per install.

“Every time a tech doesn’t have to take a NID off, patch holes, and repaint, that’s real time back,” he says. “Multiply that by hundreds of installs, and it’s a big deal.”

Less time on site means more installs per day — and that’s the kind of efficiency every service provider can appreciate.

Made by Installers, for Installers

At Precision Group, innovation doesn’t happen in a vacuum. It happens in the field.

Every product starts with a real-world problem — and ends with a simple, durable, made-to-last solution.

From the PF-ONT NID to the Cable Management Transition Plate, Precision Group continues to design products that make fiber optic ONT installs faster, cleaner, and smarter — giving technicians options, not limitations.

Explore the Solution:

Whether you’re tackling a single install or a full rollout, the Transition Plate simplifies every indoor ONT transition.

No holes. No repainting. No rework. Just a faster, cleaner way to get the job done — the Precision Group way.